technology overview

The core technology to all NarSysTech applications is our patent pending Production Potential Model (PPM). The iniitialization of the PPM involves defining the reservoir bounds and characteristics, and modeling the current production potential of the reservoir. Once the PPM is initialized it can be continually updated as new information is collected while drilling, completing and monitoring the current well. The key to this novel technology is the ability to update the model in real-time, compresing the decision workflow to minutes instead of hours or days.

Detailed Description

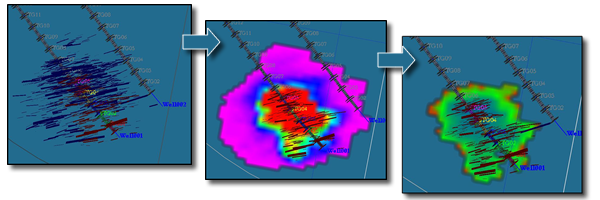

The Production Potential Model (PPM) is a finite element fractal representation of the reservoir where each element inherits the production characteristics of the well that will produce from it, computes expected production from decline curves and forecast production from each cell over time. The Production Potential Model is the core enabling technology for NarSysTech's Real-time Drainage analysis and Production Guided Interpolation products. The knowledge of when a cell starts producing and the rate of production is integral to understanding how a reservoir will drain over time and assuming that the primary change in the reservoir is related to fluid changes, it can additionally be used compute interpolation scalars between multiple time-lapse electro-magnetic or seismic volumes. The Production Potential Model provides results that correlate well with simulation generated pressure estimates, within minutes of completion, making it the only tool that can provide time-dependent drainage forecasts from static data sets collected during stimulation operations.

Frequently Ask Questions

What is the minimum data requirement to construct a PPM?

The PPM will utilize whatever data is supplied with estimates becoming more accurate and useful with more information. The minimum data required to build a model would be wells with defined perforations which would result in roughly symmetrical drainage. The minimum useful data would include hydraulic fracture monitoring data showing the reservoir response to stimulation.

How is each element’s start time computed?

Element start times are based on the distance to the perforations along the least tortuous path as defined by the flow characteristics of the element and computed using a fast-marching method.

How are the flow characteristics of each element defined?

Using the provided data, the number of fractures and fracture properties, provided with fractures or derived from logs and seismic attribute data, are used to determine the flow characteristics of each element within the PPM.

Does the PPM estimate well production?

No. The PPM is designed to honor the supplied production curves for each well and show how that production is distributed throughout the reservoir volume.

Does the PPM compete with simulation technologies?

No. The PPM needs the estimated production volumes at any point in time which requires decline curves. The source of the decline curves can be from simulation output, analog wells or internally generated mathematical functions (harmonic, exponential or linear). The PPM can be considered to extend the value of simulation results by utilizing the decline curves to predict drainage of any weal or stage in real-time.